ROI Framework: Comparing Vision, RFID-Tag, and POS Data Feeds

Effective inventory management drives business success, yet selecting the right technology can feel overwhelming. Vision systems, RFID-Tag solutions, and POS data feeds each offer unique advantages, but how do you determine which one delivers the best return on investment (ROI)? You need a structured approach to evaluate these options. By comparing their performance with a practical ROI Framework, you can make informed decisions that align with your goals and maximize value.

Key Takeaways

Use an ROI Framework to compare tools for managing inventory.

Vision tech helps by automating tasks and lowering mistakes.

RFID tags make tracking faster and more accurate, saving money.

POS data gives live updates to match stock with customer needs.

Pick tools that grow with your business and save money over time.

Overview of Technologies

Vision Technology Overview

Vision technology uses AI-driven computer vision systems to automate inventory management. These systems analyze images or video feeds to track stock levels, detect misplaced items, and identify potential theft. Businesses increasingly adopt this technology to improve operational efficiency and customer satisfaction. Retailers use computer vision to streamline stock management and enhance sales. Reports show that implementing AI-driven vision systems can boost sales by 10-15%, demonstrating their effectiveness in inventory optimization.

The growing market penetration of vision technology reflects its transformative impact on retail and e-commerce. By automating processes and reducing human intervention, you can achieve faster inventory updates and minimize errors. This technology also supports loss prevention, helping you protect your bottom line while improving customer experiences.

RFID-Tag Technology Overview

RFID-tag technology offers a powerful solution for tracking inventory with speed and precision. Unlike traditional barcodes, RFID systems can read multiple tags simultaneously, accelerating inventory checks. Automatic data collection reduces human errors, ensuring greater accuracy in stock records. Real-time monitoring allows you to respond quickly to inventory changes, preventing overstocking or shortages.

Enhanced Efficiency: RFID speeds up inventory processes by scanning multiple items at once.

Improved Accuracy: It eliminates manual data entry errors, reducing discrepancies.

Real-Time Data Monitoring: Immediate updates help you make timely decisions.

Cost-Effectiveness: While initial costs are high, long-term savings come from reduced labor and minimized losses.

RFID technology provides a scalable and reliable way to manage inventory, making it an excellent choice for businesses seeking efficiency and accuracy.

POS Data Feeds Overview

POS data feeds integrate sales data directly into inventory systems, offering real-time insights into stock levels. Cloud-based POS systems enhance forecasting accuracy, helping you predict demand and avoid stockouts. By reducing variability in the supply chain, these systems address the 'bullwhip' effect, which often leads to inefficiencies.

Adopting POS data feeds improves inventory turnover and reduces costs. You can use this technology to synchronize sales data with inventory updates, ensuring your stock aligns with customer demand. This integration minimizes waste and optimizes supply chain operations, making it a valuable tool for modern inventory management.

ROI Framework for Inventory Management

Key ROI Metrics for Evaluation

To evaluate the effectiveness of inventory management technologies, you need clear metrics that quantify performance. These metrics help you measure operational efficiency, financial impact, and customer satisfaction. Below is a table summarizing key metrics that align with the ROI Framework:

Metric Name | Formula |

|---|---|

Dead/spoiled stock | (amount of unsellable stock in period / amount of available stock in period) x 100 |

Available inventory accuracy | (# counted items that match record / # counted items) x 100 |

Internal WMS efficiency (ROI) | (gain on investment – cost of investment) / cost of investment |

[(actual – forecast) / actual] x 100 | |

Gross margin return on investment | gross margin / average inventory cost |

Inventory carrying costs | [(inventory service costs + inventory risk costs + capital cost + storage cost) / total inventory value] x 100 |

Customer satisfaction score | (# positive responses / # total responses) x 100 |

Fill rate | [(# total items – # shipped items) / # total items] x 100 |

These metrics provide a comprehensive view of how well your inventory management system performs. For example, tracking inventory accuracy ensures your records match physical stock, reducing discrepancies. Monitoring carrying costs helps you avoid tying up excessive capital in inventory. By focusing on these metrics, you can identify areas for improvement and optimize your ROI Framework.

Additionally, benchmarking against industry standards enhances your evaluation process. Comparing your metrics to established benchmarks reveals performance gaps and highlights opportunities for growth. Emerging metrics like the Digital Maturity Index and Predictive Analytics Score offer new ways to assess ROI-related performance, making your analysis even more robust.

Methodology for ROI Calculation

Calculating ROI for inventory management technologies requires a structured approach. You need to consider both direct and indirect costs, as well as tangible and intangible benefits. Below are common mathematical models used in ROI calculations:

Model | Description |

|---|---|

Determines the optimal order quantity to minimize total inventory costs, including purchasing, ordering, and holding costs. Focuses on maximizing ROI by minimizing average inventory costs. | |

Inventory Holding Cost | Emphasizes the importance of accurately estimating holding costs, including out-of-pocket cash flows and opportunity costs associated with inventory investments. |

Optimal Economic Order Quantity | Formulates EOQ under various conditions, considering demand rates and production reliability, aiming to minimize total costs and maximize profitability. |

To apply these models, start by identifying all costs associated with your chosen technology. Include initial setup costs, ongoing maintenance, and training expenses. Next, quantify the benefits, such as reduced labor costs, improved accuracy, and enhanced customer satisfaction. Use the formula:

ROI = (Gain on Investment – Cost of Investment) / Cost of Investment

For example, if implementing RFID technology reduces labor costs by $50,000 annually and costs $20,000 to install, your ROI would be:

ROI = ($50,000 - $20,000) / $20,000 = 1.5 or 150%

This calculation shows a significant return, making RFID a worthwhile investment.

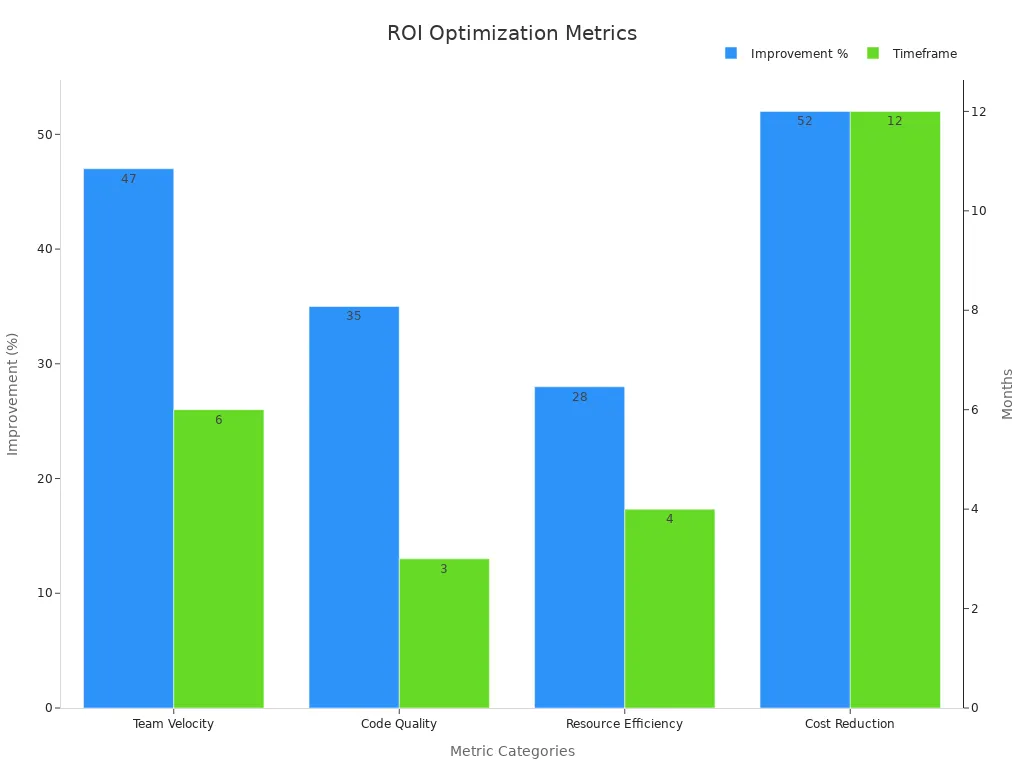

Case studies also provide valuable insights into ROI methodology. For instance, automation has led to a 30% reduction in routine operational costs and a 45% increase in employee productivity. These results demonstrate the financial and operational benefits of adopting advanced inventory management technologies.

By combining quantitative metrics, mathematical models, and real-world case studies, you can build a robust ROI Framework that guides your decision-making process.

Comparative ROI Analysis

Vision Technology ROI Analysis

Vision technology offers a modern approach to inventory management, delivering significant ROI through automation and accuracy. By eliminating manual processes, it reduces human error and ensures precise stock tracking. This technology provides several advantages:

Touchless Automation: Vision AI monitors inventory without requiring manual scans, reducing discrepancies.

Real-Time Insights: Instant alerts for low stock levels or mismatches allow you to act quickly and avoid disruptions.

Cost Efficiency: Unlike RFID systems, vision technology does not rely on expensive tags, lowering operational costs.

For example, a retailer using vision systems can achieve faster inventory updates and minimize losses from misplaced or stolen items. These benefits align with the ROI Framework by improving operational efficiency and reducing costs. Vision technology also enhances customer satisfaction by ensuring products are always available, which can lead to increased sales.

RFID-Tag ROI Analysis

RFID-tag technology excels in environments where speed and precision are critical. Its ability to scan multiple items simultaneously makes it a powerful tool for inventory tracking. Studies have shown its effectiveness in reducing inaccuracies and improving ROI:

A major retailer like Wal-Mart saved $600 million annually by minimizing out-of-stock situations with RFID implementation.

RFID systems outperform traditional inventory counting methods, offering greater accuracy and efficiency.

The cost-benefit analysis highlights long-term savings despite higher initial costs.

RFID technology aligns with the ROI Framework by reducing labor costs and improving inventory accuracy. Real-time data collection allows you to make informed decisions, preventing overstocking or shortages. While the upfront investment may seem high, the long-term gains in efficiency and cost savings make RFID a worthwhile choice for many businesses.

POS Data Feeds ROI Analysis

POS data feeds integrate sales data with inventory systems, providing actionable insights that drive ROI. This technology helps you optimize inventory management, understand customer behavior, and boost retail margins. The following table highlights its contributions:

Contribution to Inventory Management ROI | |

|---|---|

Optimizing inventory management | Tracks product sales, enabling timely reordering and reducing waste, which increases profitability. |

Understanding customer behavior | Provides insights into buying habits, allowing for targeted marketing and efficient inventory planning, enhancing customer experience. |

Boosting retail margins | Facilitates quick decision-making on pricing and promotions based on real-time data, optimizing profits and minimizing losses. |

By leveraging POS data feeds, you can align inventory levels with customer demand, reducing carrying costs and improving turnover rates. This technology supports the ROI Framework by enhancing decision-making and streamlining operations. Its ability to provide real-time insights ensures that your business remains agile and responsive to market changes.

Implementation Insights for ROI Optimization

Cost and Scalability Considerations

When implementing inventory management technologies, you must evaluate both upfront and ongoing costs. Initial investments for software, hardware, and installation can range from $10,000 to $20,000 for smaller businesses. Monthly expenses for subscriptions, maintenance, and training typically fall between $500 and $1,000. Hidden costs, such as infrastructure upgrades or customizations, may also arise. These factors can significantly impact your budget.

Scalability is another critical consideration. Choosing a system that grows with your business prevents costly migrations later. For example, a scalable warehouse management system (WMS) ensures seamless expansion as your inventory needs increase. Sensitivity analyses reveal that bundled intangibles, like software adaptability, can cause up to 10% fluctuations in costs and revenues.

Cost Category | Description |

|---|---|

Upfront Costs | Initial investments for software, installation, and hardware, typically ranging from $10,000 to $20,000 for smaller businesses. |

Ongoing Costs | Monthly expenses for subscriptions, maintenance, and training, which can range from $500 to $1,000. |

Hidden Costs | Additional expenses such as customizations and infrastructure upgrades that may not be immediately apparent. |

Scalability | Importance of choosing a WMS that can grow with the business, avoiding costly migrations later. |

Integration with Existing Systems

Integrating new technologies with your current systems can streamline operations and maximize ROI. However, this process requires careful planning. You need to ensure compatibility between the new system and your existing software, such as enterprise resource planning (ERP) or customer relationship management (CRM) tools. Analytical software can assist in real-time performance tracking, helping you identify integration gaps early.

Taking an iterative approach with stakeholders ensures alignment throughout the integration process. Regular feedback sessions help address challenges and refine workflows. Benchmarks and peer insights also provide valuable guidance. For instance, businesses that adopt balanced scorecards and key performance indicators (KPIs) often achieve better system reliability and process efficiency.

Training and Maintenance Challenges

Training your team to use new inventory management technologies is essential for success. Without proper training, employees may struggle to adapt, leading to inefficiencies. You should allocate time and resources for comprehensive training programs. These programs should focus on both technical skills and practical applications.

Maintenance is another challenge. Regular updates and troubleshooting are necessary to keep systems running smoothly. AI integration, for example, can improve efficiency by 28% and increase EBIT by at least 5%. However, these benefits depend on consistent system upkeep. Transparent methodologies and clear documentation can simplify maintenance tasks, ensuring long-term success.

By addressing these challenges proactively, you can optimize your ROI and ensure a smooth implementation process.

Choosing the right inventory management technology depends on understanding its strengths and trade-offs. Vision systems excel in automation and accuracy, RFID tags offer unmatched speed and precision, and POS data feeds provide real-time insights for decision-making. Each technology delivers unique ROI benefits, but your choice should align with your business goals.

To simplify your decision, consider the following comparison:

Software | Strengths | Trade-Offs |

|---|---|---|

Software A | Heavyweight in computational power | May be complex for new users |

Software B | Flexibility and customization from open-source | Requires more setup and learning |

Software C | User-friendly interface with robust visualization | May lack some advanced features of competitors |

Focus on scalability, ease of integration, and long-term cost efficiency. By aligning technology adoption with your objectives, you can maximize ROI and streamline operations effectively.

FAQ

What is the most cost-effective technology for small businesses?

RFID-tag technology often provides the best balance of cost and efficiency for small businesses. While the initial investment may seem high, long-term savings from reduced labor costs and improved accuracy make it worthwhile.

Tip: Start with a pilot program to assess scalability before full implementation.

How do I calculate ROI for these technologies?

Use the formula:

ROI = (Gain on Investment – Cost of Investment) / Cost of Investment

Identify all costs (setup, maintenance) and benefits (reduced labor, improved accuracy). For example, if RFID saves $50,000 annually and costs $20,000 to install, ROI = 150%.

Can these technologies work together?

Yes, integrating Vision, RFID, and POS systems can enhance inventory management. Vision provides real-time monitoring, RFID ensures accuracy, and POS aligns stock with sales data. Together, they create a seamless, efficient system.

Note: Ensure compatibility between systems before integration to avoid technical issues.

How long does it take to see ROI improvements?

Most businesses see ROI improvements within 6–12 months after implementation. Factors like training, system integration, and business size can influence this timeline.

Emoji Insight: ⏳ Patience pays off! Proper planning accelerates ROI realization.

What are the biggest challenges in adopting these technologies?

Common challenges include high upfront costs, integration with existing systems, and employee training. Regular maintenance also requires attention. Addressing these proactively ensures smoother adoption and better ROI.

Pro Tip: Allocate resources for training and system updates to minimize disruptions.

See Also

Comparing IoT Sensors And Camera Analytics For Key Metrics

Utilizing Computer Vision Heatmaps For A/B Testing Layouts

Selecting The Best Model: RFM, Cohort, Or CLV?

Creating Funnel Reports To Analyze Browsing And Purchase Trends