Competitors Using Logistics Forecasting and Dynamic Adjustment

Competitors Using Logistics forecasting now rely on AI and machine learning to improve accuracy and cut costs. They quickly adapt to market changes and boost supply chain resilience. Many companies see real-time operational gains and stronger market positions. Industry reports show rapid growth as more organizations turn to these advanced solutions. Businesses that ignore these trends risk falling behind in a fast-changing environment.

Key Takeaways

Logistics forecasting uses data and AI to predict demand accurately, helping companies avoid overstocking and stockouts.

Dynamic adjustment lets businesses quickly change plans using real-time data, improving response to market shifts and disruptions.

Advanced technologies like AI, machine learning, and real-time tracking boost efficiency, cut costs, and enhance customer satisfaction.

Building a data-driven culture and tracking key performance metrics help companies improve continuously and stay competitive.

Overcoming challenges like data quality and employee resistance is essential for successful implementation and long-term growth.

Competitors Using Logistics Forecasting: What and Why

Defining Logistics Forecasting

Logistics forecasting predicts future supply chain needs using data and technology. Companies analyze sales trends, customer behavior, and economic indicators to estimate demand. This process helps businesses avoid overstocking or running out of products. Many organizations now use AI and machine learning to improve forecast accuracy. These tools process large datasets, uncover hidden patterns, and adapt to new information in real time. Companies like Amazon and Sephora use machine learning to predict sales and customer trends, which reduces costs and improves service levels. Demand-driven forecasting aligns supply with actual customer needs, leading to higher satisfaction and better resource allocation.

Tip: Demand forecasting software outperforms traditional methods by considering hundreds of influencing factors, reducing stockouts, and avoiding overbuying.

Understanding Dynamic Adjustment

Dynamic adjustment refers to the ability to change logistics plans quickly based on real-time data. Companies monitor key performance indicators (KPIs) such as order accuracy, delivery times, and inventory levels. Real-time monitoring systems track these KPIs and send alerts when performance shifts. Automated tools help managers respond fast to unexpected changes, such as supply disruptions or sudden spikes in demand. Scenario modeling and predictive analytics allow organizations to test different strategies and prepare for various outcomes. This flexibility supports continuous improvement and risk management.

Risk-adjusted KPIs provide a full view of operational health.

Automated alerts enable rapid intervention.

Scenario modeling helps companies understand potential performance ranges.

The Importance in Today’s Market

Competitors Using Logistics forecasting and dynamic adjustment gain a clear edge in today’s fast-paced market. Analytics optimize supply chain operations, reduce empty miles, and improve cost efficiency. AI-powered models increase fleet utilization and lower operational costs. Accurate forecasting prevents overstocking and stockouts, saving money and ensuring products are available when needed. Companies that excel in these areas see measurable improvements, such as a 1% sales increase, up to 5% cost reduction, and 5-20% inventory reduction. Continuous refinement of forecasts using real-time data helps businesses adapt to market changes and maintain customer satisfaction. Competitors Using Logistics strategies position themselves for sustainable growth and operational agility.

Competitive Advantages of Competitors Using Logistics

Cost Savings and Resource Optimization

Companies that invest in logistics forecasting and dynamic adjustment see significant cost savings. They use advanced analytics to track key performance indicators such as on-time delivery rates, cargo capacity, and fuel consumption. Regular freight audits help uncover billing errors and reduce unnecessary charges. Automation in warehouses, like order picking and packing, lowers labor costs and reduces mistakes. Technologies such as RFID and IoT sensors provide real-time tracking, which helps companies use resources more efficiently. For example, a mid-size retailer that adopted lean logistics practices reduced distribution costs by over 20% in one year. The order fulfillment cycle also improved from 48 hours to 36 hours. These results show how Competitors Using Logistics can optimize resources and cut costs by using data-driven strategies.

Boosting Operational Efficiency

Logistics forecasting improves operational efficiency by helping companies predict demand and manage inventory better. Accurate forecasting prevents both stockouts and overstocking, which keeps operations running smoothly. Companies use data analytics to plan production, procurement, and distribution. This planning leads to faster order fulfillment and less downtime. Many organizations now use telematics data to predict when vehicles need maintenance, which reduces breakdowns and extends vehicle life. Real-time visibility and predictive analytics allow managers to make quick decisions and respond to changes in the supply chain. Companies also optimize warehouse layouts and fleet usage to save time and money.

Proactive fleet maintenance reduces downtime.

Real-time analytics improve decision-making and resource allocation.

Enhancing Customer Satisfaction

Dynamic adjustment in logistics directly impacts customer satisfaction. Companies monitor metrics like Net Promoter Score (NPS), customer reviews, and conversion rates to understand customer needs. Real-time dashboards help track these metrics and ensure service quality. By predicting demand accurately, companies keep products in stock and deliver orders on time. This reliability builds trust and encourages repeat business. Regular reviews of customer feedback allow companies to adjust their logistics strategies quickly. As a result, customers experience fewer delays and better service, which increases loyalty and long-term value.

Note: Aligning logistics forecasting with business goals not only reduces costs but also improves customer service and supports innovation. Companies like Amazon use these strategies to offer same-day delivery, which boosts satisfaction and market share.

Rapid Response to Market Shifts

Companies face constant changes in the market. Quick adaptation often determines success or failure. Competitors Using Logistics forecasting and dynamic adjustment respond to market shifts faster than others. They use real-time data and advanced analytics to make immediate decisions. This approach helps them avoid costly delays and missed opportunities.

Many industries have shown the value of rapid response. During the COVID-19 pandemic, manufacturers revised forecasting models to handle supply chain disruptions and unpredictable demand. The automotive sector adjusted quickly when semiconductor shortages threatened production. Electronics companies like Apple used predictive analytics to change production schedules and meet sudden spikes in demand, especially during new product launches.

Key strategies for rapid response include:

Revising forecasting models to address supply chain disruptions and demand changes.

Using predictive analytics to adjust production schedules for sudden demand spikes.

Combining expert judgment, market research, and machine learning for better forecasting.

Integrating real-time data from IoT devices and AI-driven analytics to refine forecasts and make immediate adjustments.

Encouraging collaboration between sales, marketing, and operations to improve forecasting accuracy and support quick decisions.

These methods reduce the risk of overproduction or stockouts. Real-time data integration allows companies to spot problems early and act before issues grow. Collaboration across departments ensures everyone works toward the same goals. Companies that master these techniques stay ahead of competitors and maintain strong market positions.

Competitors Using Logistics strategies show that rapid response is not just possible but essential. Businesses that invest in these capabilities can handle sudden changes and keep customers satisfied. Quick adaptation leads to fewer losses and more opportunities for growth.

Technologies and Methods Competitors Using Logistics Employ

AI and Machine Learning in Forecasting

AI and machine learning have changed how companies predict demand and manage supply chains. These technologies process large amounts of data, spot patterns, and update forecasts as new information arrives. Many companies now see measurable improvements. For example, AI has improved forecast accuracy by 10%, reduced inventory costs by 15%, and decreased stockout events by 13%. AI also helps companies make better decisions by finding trends and possible disruptions early. It automates data collection, which saves time and boosts productivity. In weather forecasting, deep learning models capture complex climate patterns that older models miss. These advances help companies in many industries, from retail to agriculture, save money and improve service.

Improvement Metric | Measurable Improvement |

|---|---|

Forecast accuracy | Improved by 10% |

Inventory costs | Reduced by 15% |

Stockout events | Decreased by 13% |

Real-Time Data Integration

Real-time data integration gives companies a clear view of their supply chains. They track shipments, vehicles, and inventory at every stage. This visibility helps managers spot problems early and make quick decisions. Companies use IoT devices, AI, and stream processing to collect and analyze data as it happens. Real-time tracking improves route planning, reduces fuel use, and lowers inventory costs. It also helps companies provide accurate delivery estimates and fast customer support. Businesses like Maersk and Unilever use real-time data to cut shipping delays and keep customers happy. These methods help Competitors Using Logistics stay ahead by making their operations more efficient and reliable.

Tip: Real-time data lets companies reroute shipments and adjust inventory strategies before problems grow.

Predictive Analytics and Scenario Planning

Predictive analytics helps companies plan for the future. They use models that look at past sales, seasonal trends, and outside factors. This approach reduces stockouts and keeps inventory at the right level. Companies also use scenario planning to test different strategies. For example, lululemon used predictive analytics to plan for international growth and improve financial health. In retail, predictive models help companies meet customer demand and avoid lost sales. City planners and hospitals use these tools to manage resources and prepare for changes. By combining predictive analytics with scenario planning, companies can prepare for best- and worst-case outcomes. This reduces risk and supports better decision-making.

Combining quantitative and qualitative forecasting methods improves accuracy.

Collaborative planning across departments reduces blind spots.

Continuous model updates based on performance metrics help companies adapt to market changes.

Automated Decision-Making Tools

Automated decision-making tools have transformed logistics operations for leading companies. These tools use algorithms and data analytics to make fast, accurate choices without human delay. Many organizations now rely on these systems to handle complex supply chain decisions, such as inventory management, order routing, and risk assessment.

Companies like Amazon and Walmart use automated systems to process orders, manage stock, and optimize delivery routes. These tools analyze large amounts of data in real time. They identify trends, predict demand, and adjust operations instantly. As a result, businesses see major improvements in efficiency and accuracy.

Key operational improvements linked to automated decision-making tools include:

Trading efficiency increased by 50%, with a 65% drop in operational errors.

Walmart improved inventory turnover by 25% and reduced out-of-stock incidents by 40%.

Amazon’s automated fulfillment systems cut order processing time by 50% and achieved 99.9% accuracy.

Companies reported up to 40% fewer product defects, leading to higher customer satisfaction.

Operational costs dropped by 15-25%, while resource utilization improved by 30-40%.

Waste reduced by 20-30%, and financial institutions lowered loss exposure by up to 35%.

Automated decision-making tools also boost productivity by 20-30%. They process large data volumes quickly, which helps companies spot patterns and make better predictions. These systems support continuous learning and compliance, reducing risks and improving customer satisfaction.

Automated tools help companies make consistent, data-driven decisions. This reduces human error and speeds up every step of the logistics process.

By adopting automated decision-making tools, competitors gain a clear advantage. They respond faster to market changes, cut costs, and deliver better service. These benefits show why automated systems have become essential in modern logistics.

Implementing Logistics Forecasting and Dynamic Adjustment

Evaluating Current Logistics Capabilities

Companies must first understand their existing logistics strengths and weaknesses before making improvements. They assess performance using key metrics that cover transportation, warehousing, financial, and operational areas. These metrics help leaders spot bottlenecks, track progress, and set realistic goals.

KPI Name | Description and Importance |

|---|---|

Ratio of actual production to maximum production, showing ability to handle demand increases | |

Equipment Utilization Rate | Measures if equipment matches job needs; targets 70%-90% utilization to avoid delays or excess costs |

Use of Packing Material | Tracks packaging material usage to reduce costs and environmental impact |

Pick and Pack Cycle Time | Time taken to pick and pack an order, used to identify inefficiencies |

Number of Shipments | Counts orders shipped, helps identify peak periods for resource planning |

Truck Turnaround Rate | Time trucks spend at warehouse, measuring loading/unloading efficiency |

Driver Performance | Composite metric including speed, idle time, braking, used to improve safety and maintenance |

Fuel Efficiency | Measures vehicle fuel performance, impacting operating costs |

Lead Time (Order Cycle Time) | Time from order placement to receipt, critical for customer satisfaction |

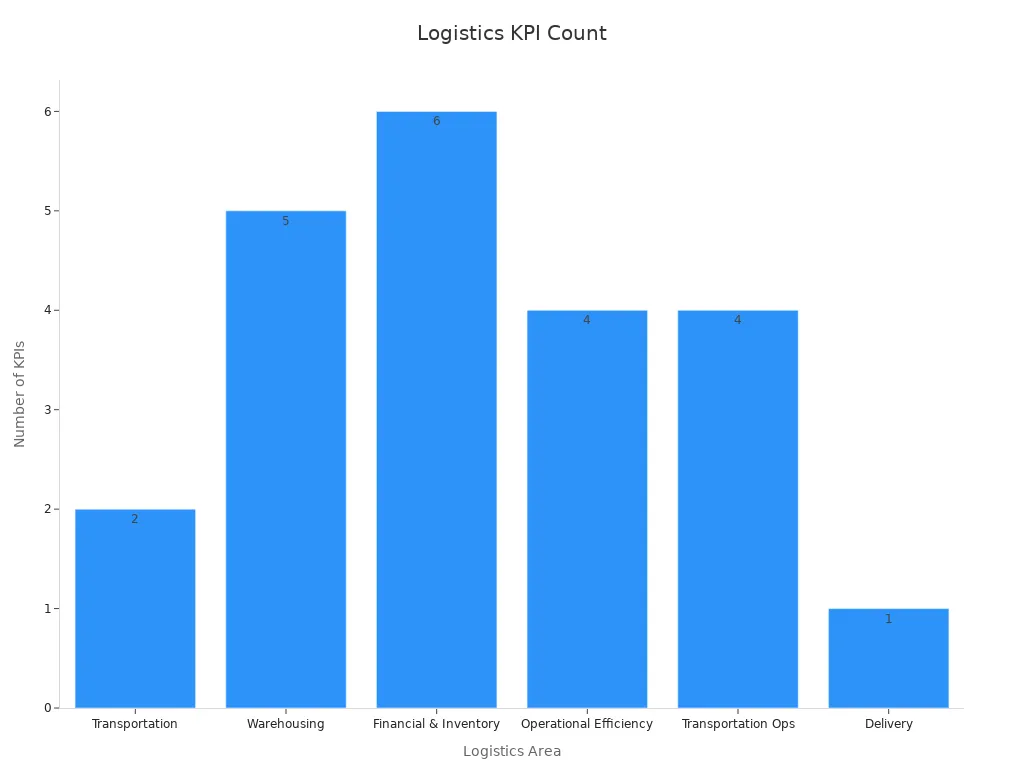

Managers also review metrics by logistics area to get a complete picture:

Logistics Area | |

|---|---|

Transportation | On-Time Final Delivery, Cost Per Pound |

Warehousing | Inventory Accuracy, Yard/Dock to Stock Time, On-Time Shipping, Order Accuracy, Fill Rate |

Financial & Inventory | Pick and Pack Costs, Operating Ratio, Net Profit Ratio, Inventory Turnover Ratio, Financial Leverage, Inventory to Sales Ratio |

Operational Efficiency | Equipment Utilization Rate, Capacity Utilization, Use of Packing Material, Pick and Pack Cycle Time |

Transportation Ops | Number of Shipments, Truck Turnaround Rate, Driver Performance, Fuel Efficiency |

Delivery | Lead Time (order placement to receipt duration) |

Tip: Regularly tracking these KPIs helps companies spot inefficiencies and make data-driven decisions for continuous improvement.

Selecting and Integrating Advanced Technologies

After evaluating current capabilities, companies choose technologies that fit their needs and business models. They look for solutions that offer clear benefits, such as cost savings, better visibility, and faster operations. The right mix of tools can transform logistics performance.

Technology | Evidence Summary | Quantified Impact / Metrics |

|---|---|---|

Enables strategic carrier use and reduces spot market reliance. | Primary carrier usage increased from 75% to 90%; spot market use reduced from ~2.5% to 0.5%; significant transportation cost savings. | |

Digital Freight Bidding | Automates freight bidding, optimizing cost and service balance. | Truckload costs reduced by up to 12%; value realized within 12 weeks via SaaS model. |

Digital Control Towers + TMS | Provides real-time visibility and predictive analytics for supply chain disruptions and responses. | Estimated $14.1 million transportation savings over 3 years for a $10 billion company. |

Warehouse Task Automation | Optimizes labor and processes in warehouses using ML-driven task scheduling. | Over $31.2 million cost savings over 3 years for a $10 billion company; improves labor productivity. |

Warehouse Robotics | Scales warehouse operations with intelligent robots, reducing labor dependency and integration time. | Market growing at 13.2% annually; DHL reduced robotics integration time by 60%, targeting 90% reduction; faster ROI. |

Companies often start with digital control towers and transportation management systems (TMS) to gain real-time supply chain visibility. These tools help managers respond quickly to disruptions and optimize routes. Warehouse automation and robotics further boost productivity and reduce labor costs. Digital freight bidding and dynamic price discovery streamline carrier selection and lower transportation expenses.

Note: Integrating these technologies requires careful planning and change management. Leaders must ensure systems work together and staff receive proper training.

Fostering a Data-Driven Culture

A data-driven culture empowers employees at all levels to use information for better decisions. Companies that embrace this mindset see faster delivery, lower costs, and improved inventory management. Amazon and Walmart lead by example, using advanced algorithms and real-time data to optimize logistics.

Company | Benefit | Measurable Outcome | Description |

|---|---|---|---|

Amazon | Inventory Optimization | Faster delivery, lower transport costs | Uses advanced algorithms analyzing consumer behavior to optimize inventory distribution. |

Walmart | Excess Inventory Reduction | Up to 20% reduction | Employs forecasting models combining real-time sales and external factors to reduce stock. |

Other organizations report similar gains:

Benefit | Measurable Outcome | Description |

|---|---|---|

Up to 25% reduction | Achieved through predictive maintenance enabled by frontline employees empowered with data. | |

Cost Savings from Carrier Penalties | $1.2 million annual savings | Resulting from intelligent warehouse appointment scheduling using machine learning. |

Turnaround Time Reduction | 16% reduction | Achieved by optimizing carrier appointment scheduling across multiple warehouses. |

Increased Profitability | 19 times more likely to be profitable (McKinsey) | Data-driven organizations show significantly higher profitability compared to non-data-driven. |

Employee Empowerment | Qualitative improvement | Frontline workers trained to interpret data make timely decisions, reducing delays and costs. |

Callout: Data-driven cultures also boost employee engagement. When companies celebrate data successes, they motivate teams to keep improving and support new technology adoption.

To build this culture, leaders invest in training, encourage collaboration, and reward data-based achievements. They appoint data ambassadors who help teams learn and share best practices. Over time, these efforts create momentum for ongoing innovation and operational excellence.

Overcoming Implementation Challenges

Companies often face several obstacles when they implement logistics forecasting and dynamic adjustment strategies. These challenges can slow progress and reduce the benefits of new technologies. Leaders must recognize these issues early and address them with proven solutions.

Challenge | Description | Solution |

|---|---|---|

Poor data quality, inconsistent and incomplete data across sources reduces model reliability. | Establish data governance, implement strict data cleaning, use ETL tools for integration. | |

Managing Large Data Volumes | Difficulty storing and processing huge datasets with traditional systems. | Use scalable cloud storage and big data technologies to handle volume and processing needs. |

Lack of Clear Objectives and Strategy | Absence of defined goals leads to misaligned analytics efforts and wasted resources. | Define clear objectives and KPIs aligned with business goals to guide analytics projects. |

Inadequate Technology and Infrastructure | Legacy systems lack capacity and flexibility for modern analytics. | Upgrade infrastructure, adopt modular and cloud-based architectures for scalability. |

Resistance to Change | Employee hesitation and fear of automation hinder adoption. | Foster data-driven culture, involve leadership, provide training and support. |

Many organizations struggle with data quality and integration. Inconsistent or incomplete data can make forecasting models unreliable. Companies that succeed set up strong data governance and use advanced tools to clean and combine data from different sources. Managing large data volumes also presents a challenge. Traditional systems often cannot handle the scale of modern logistics data. Scalable cloud storage and big data platforms help companies process information quickly and efficiently.

A lack of clear objectives can lead to wasted resources. Teams may work hard but fail to deliver results if they do not align their efforts with business goals. Setting clear objectives and key performance indicators (KPIs) keeps projects on track. Inadequate technology and outdated infrastructure can slow down progress. Companies that invest in modular, cloud-based systems gain flexibility and can scale operations as needed.

Resistance to change remains a common barrier. Employees may worry about automation or feel unsure about new processes. Leaders who foster a data-driven culture, involve staff in decision-making, and provide training see higher adoption rates. Walmart, for example, optimized its supply chain analytics to reduce stockouts and excess inventory, which led to significant cost savings and better efficiency. Netflix improved viewer retention by using predictive analytics to personalize content, showing how clear strategy and employee buy-in drive success.

Tip: Involve employees early in the process and celebrate small wins. This approach builds trust and encourages teams to embrace new technologies.

Continuous Monitoring and Improvement

Continuous monitoring ensures that logistics forecasting strategies deliver long-term value. Companies track key performance indicators (KPIs) across cost, efficiency, risk, and customer experience to measure progress and spot areas for improvement.

Metric Category | Examples of KPIs Monitored | Purpose |

|---|---|---|

Cost-saving metrics | Fuel consumption, labor costs, inventory turnover ratio | Track operational cost reductions |

Efficiency metrics | On-time delivery rate, warehouse throughput, picking accuracy | Measure delivery and warehouse performance improvements |

Risk management metrics | Unplanned downtime, supplier failures, mean time between failures | Monitor supply chain disruptions and maintenance effectiveness |

Customer experience metrics | Order processing time, return rates, order accuracy | Ensure improved customer satisfaction and fulfillment |

Companies like Nike use AI-driven demand forecasting to reduce inventory holding costs by 20% and improve product availability. Predictive maintenance powered by IoT sensors helps anticipate equipment failures, which lowers unplanned downtime and maintenance expenses. The Singapore Port Authority uses digital twin technology to simulate and optimize logistics operations in real time, leading to continuous improvements in infrastructure and workflow.

A structured return-on-investment (ROI) measurement framework aligns analytics projects with business goals. This framework allows companies to benchmark their performance against industry standards and adjust strategies as needed. For example, a Swiss chemical company achieved 97-98% forecasting accuracy by combining different models, which saved time and reduced manual errors. The same company increased production speed by 15% and overall equipment effectiveness (OEE) by 8%, resulting in an eightfold return on investment.

Note: Regularly reviewing KPIs and benchmarking against industry leaders helps companies maintain high standards and adapt to changing market conditions.

Continuous improvement depends on feedback loops. Teams analyze performance data, identify gaps, and implement targeted changes. This cycle keeps logistics operations agile and competitive. Companies that monitor and refine their strategies stay ahead of the competition and deliver better results year after year.

Logistics forecasting and dynamic adjustment give companies a strong edge. Advanced models improve demand prediction and help leaders make better decisions. Key benefits include:

Better resource allocation and inventory management

Faster response to market changes

Improved customer satisfaction

Companies that use real-time data and predictive analytics see lower costs and greater efficiency.

Continuous monitoring and process innovation keep businesses ahead of competitors.

Companies that act now can avoid falling behind and secure long-term growth.

FAQ

What is logistics forecasting?

Logistics forecasting uses data and technology to predict future supply chain needs. Companies analyze trends and patterns to estimate demand. This process helps businesses plan inventory, reduce costs, and improve service.

How does dynamic adjustment benefit companies?

Dynamic adjustment allows companies to change logistics plans quickly. They use real-time data to respond to disruptions or demand spikes. This flexibility helps maintain smooth operations and keeps customers satisfied.

Which technologies support logistics forecasting?

Companies use AI, machine learning, IoT sensors, and predictive analytics. These tools process large datasets, provide real-time insights, and automate decision-making. They help businesses improve accuracy and efficiency.

What challenges do companies face when adopting these strategies?

Companies often struggle with data quality, outdated systems, and employee resistance. Leaders address these issues by investing in new technology, training staff, and setting clear goals.

Why should businesses prioritize logistics forecasting and dynamic adjustment?

Businesses that use these strategies gain a competitive edge. They lower costs, improve efficiency, and respond faster to market changes. This approach supports long-term growth and customer loyalty.

See Also

Creating Adaptive Feedback Systems For Real-Time ETA Adjustments

Effective Weekly Retail Demand Prediction Techniques And Approaches

Techniques And Challenges In Short-Term Demand Forecasting

Developing Data-Based Stage-Gate Processes For Retail Launches

Reasons Static Delivery Schedules Collapse In Same-Day Retail