Order Forecast and what retailers overlook in digital transformation

Retailers often miss vital elements during digital transformation. Real-time demand sensing, external data integration, and supply chain digitization play a key role in accurate Order Forecast. Many overlook frontline employee engagement, which leads to errors in predictions. Missed opportunities can result in excess stock or empty shelves. Reliable forecasting supports better inventory management, improves customer satisfaction, and drives business growth.

Focusing on these overlooked factors helps retailers achieve lasting success in a competitive market.

Key Takeaways

Good order forecasting helps stores keep the right items in stock.

This saves money and makes customers happy.

Many stores forget to use live data and market news.

They also do not ask workers for ideas.

This makes their guesses less correct and hurts business.

Updating old computer systems helps stores make faster choices.

More digital tools mean fewer mistakes in ordering and stocking.

When teams work together, they share information better.

This helps them answer problems quickly and guess needs better.

Using AI and cloud tools helps stores know what people want.

Stores can change plans fast and grow their business.

Why Order Forecast Accuracy Is Essential

Inventory Optimization and Supply Chain Efficiency

Accurate Order Forecast helps retailers keep the right amount of stock on hand. When companies use real-time demand sensing and supply chain digitization, they can reduce safety stock by up to 30% and save up to 20% in costs. Walmart and Target use these methods to adjust inventory quickly, which lowers the risk of running out or having too much stock.

Metric | Numerical Statistic | Impact Description |

|---|---|---|

Safety Stock Reduction | Up to 30% | Dynamic demand sensing improves inventory levels |

Cost Savings from AI-enabled Supply Chains | Up to 20% | AI-driven models cut supply chain costs |

Forecast Accuracy Improvement | Significant (qualitative) | Advanced analytics boost forecast reliability |

Retailers use strategies like ABC analysis and Vendor-Managed Inventory to plan stock levels. AI and machine learning help automate these decisions, making supply chains more efficient and responsive.

Impact on Customer Experience and Revenue

Order Forecast accuracy directly affects customer satisfaction and sales. When stores have the right products available, customers trust the brand and return for future purchases. Stockouts can cause about 4% in lost sales, which means $40 million lost per $1 billion in sales. AI-based forecasting can reduce product unavailability by up to 65%, leading to higher sales and happier customers.

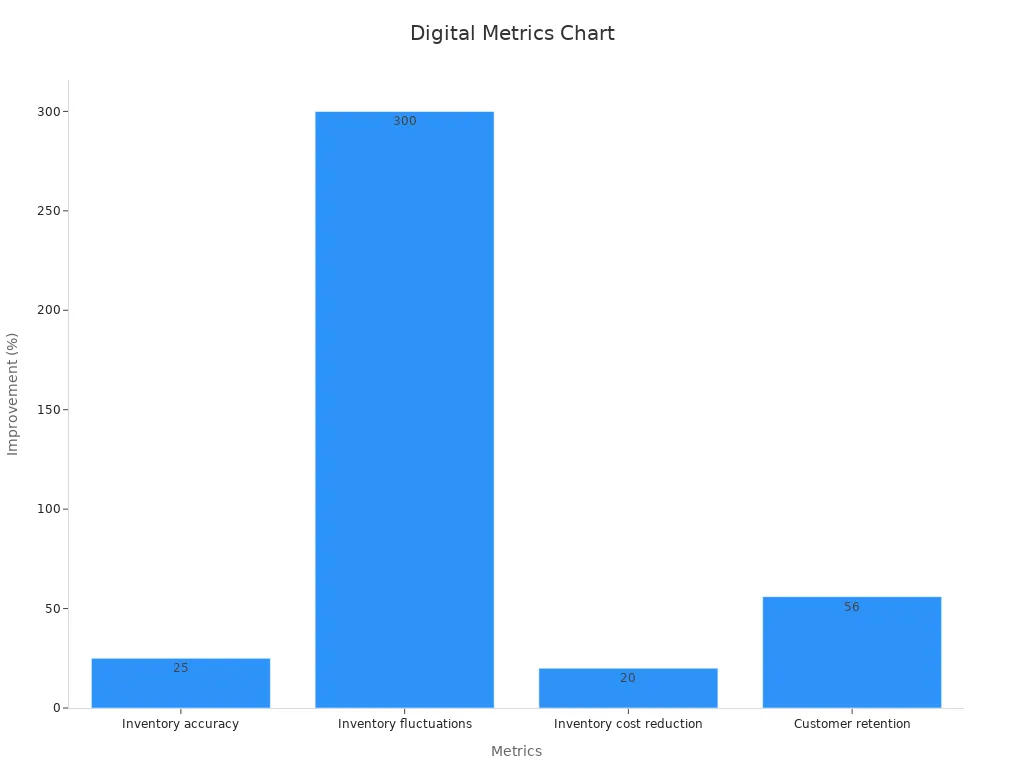

Retailers using modern data analytics see up to 25% better inventory accuracy and 89% customer retention with strong omnichannel strategies. These improvements also lower costs and boost repeat business.

Gaining a Competitive Edge

Retailers who invest in accurate Order Forecast gain a clear advantage. A European food retailer saved $20 million each year by using AI-powered demand sensing. Companies also saw a 10% drop in trucking costs and doubled their inventory turns. Forecast accuracy improved from about 60% to over 80%, reducing errors by up to 40%.

Avoid costly overstocks, which globally cost retailers $554 billion in 2024.

Reduce missed delivery windows, lowering expedited shipment costs.

Provide better pre-purchase delivery transparency, influencing 63% of shoppers' purchase decisions.

Optimize resource allocation including staff, inventory, warehouse space, and transportation capacity.

Retailers like Amazon and Walmart use AI to predict demand, manage stock, and improve customer experience. These actions help them stay ahead in a fast-changing market.

Commonly Overlooked Elements in Digital Transformation

Underutilization of Real-Time and External Data

Many retailers still depend on internal historical data for their Order Forecast. This approach limits their ability to see the full market picture. Real-time and external data, such as market trends, economic indicators, and competitor activity, provide valuable insights that internal data alone cannot reveal. When retailers ignore these sources, they miss early signs of market shifts and changes in consumer behavior.

Accurate forecasting requires both internal and external data for a complete view.

Poor data quality and lack of integration often reduce forecast accuracy.

Overreliance on historical data leads to missed revenue targets and poor inventory management.

Next-generation AI and machine learning can analyze complex datasets and update forecasts in real time.

A data-centric approach improves decision-making, agility, cost efficiency, and customer satisfaction.

Studies from Gartner and Forrester show that integrating external data sources can improve forecasting accuracy by 10-12%. Retailers who expand their data inputs and use business intelligence dashboards gain clearer analysis and faster responses. The CFO often leads the push for a data-driven culture and strong data governance, which are essential for successful forecasting.

Tip: Retailers should link insights from external data directly to business processes for faster action and better results.

Overreliance on Legacy Systems and Low Supply Chain Digitization

Legacy systems create major barriers to digital transformation. Many retailers still use manual paperwork, phone calls, or outdated software. These systems do not connect well with modern digital platforms, causing data silos and communication gaps. As a result, real-time information sharing becomes difficult, and forecasting errors increase.

Legacy systems slow down data flow and limit real-time visibility.

Different levels of technology among supply chain partners make collaboration harder.

Low digitization means less real-time tracking and fewer predictive analytics tools.

Traditional supply chains rely on fragmented data and reactive decisions, which often lead to mistakes.

Digital supply chains use AI, IoT, and cloud computing to enable predictive analytics and real-time insights. For example, Walmart uses machine learning and big data to optimize stock replenishment and improve demand forecasting. A McKinsey report found that digitization improves logistics costs and service levels, which supports better forecasting and supply chain efficiency.

Note: Upgrading to digital systems helps retailers reduce errors and respond faster to market changes.

Siloed Operations and Lack of Departmental Integration

Siloed operations remain a common problem in retail organizations. Departments such as marketing, sales, and supply chain often work separately, each using its own data and processes. This lack of integration leads to inconsistent information and slow decision-making.

Siloed teams may not share critical data, causing gaps in the Order Forecast.

Without cross-departmental collaboration, retailers struggle to align inventory with actual demand.

Disconnected operations make it harder to respond to sudden changes in the market.

Retailers who break down these silos and encourage collaboration see better results. Integrated teams can share insights, align goals, and act quickly. This approach leads to more accurate forecasts, improved inventory management, and a stronger customer experience.

Callout: Building a culture of collaboration and data sharing helps retailers stay agile and competitive.

Insufficient Frontline Employee Engagement and Training

Frontline employees play a critical role in the success of any retail operation. They interact with customers, manage inventory, and handle daily store activities. Many retailers overlook the importance of engaging and training these employees during digital transformation. This oversight can lead to inaccurate data entry, missed sales signals, and poor adoption of new technologies.

When frontline staff do not understand new systems, they may resist change or make mistakes. Training programs often focus on management or IT teams, leaving store associates behind. Retailers who invest in ongoing training see better results. Employees who feel confident using digital tools can spot trends, report issues quickly, and support accurate Order Forecast.

Note: Engaged employees act as the eyes and ears of the business. Their feedback helps refine forecasting models and improve store performance.

Retailers can boost engagement by:

Offering regular, hands-on training sessions.

Providing clear communication about the benefits of new systems.

Recognizing and rewarding employees who contribute valuable insights.

Creating feedback loops between store teams and central planners.

A well-trained frontline team ensures that data flows smoothly from the sales floor to the forecasting system. This approach reduces errors and supports better business decisions.

Neglecting Brick-and-Mortar Forecasting Challenges

Physical stores face unique challenges that digital-only retailers do not encounter. Many forecasting models focus on online sales and overlook the complexities of brick-and-mortar locations. Factors such as local events, weather changes, and in-store promotions can cause sudden shifts in demand.

Store managers often rely on intuition or outdated reports to make stocking decisions. This practice can lead to overstocked shelves or empty displays. Retailers who ignore these challenges risk losing sales and damaging customer trust.

Key challenges for brick-and-mortar forecasting include:

Fluctuating foot traffic due to local events or holidays.

Regional differences in product preferences.

Limited visibility into real-time inventory levels.

Manual processes that slow down data collection.

A table below highlights common issues and their impact:

Challenge | Impact on Store Performance |

|---|---|

Unpredictable local demand | Increased stockouts or overstocks |

Manual inventory tracking | Delayed response to sales trends |

Lack of real-time data | Missed opportunities for promotions |

Retailers can address these issues by integrating store-level data into their Order Forecast process. Using sensors, mobile apps, and real-time dashboards helps managers respond quickly to changing conditions. This strategy leads to more accurate forecasts and a better shopping experience for customers.

Leveraging Data and Technology for Better Order Forecasts

Integrating Real-Time Demand Sensing

Retailers now use real-time demand sensing to capture up-to-the-minute changes in customer behavior. This approach combines internal data, such as sales and inventory, with external signals like weather and economic trends. For example, Tacori improved its demand sensing by merging CRM and supply chain data with weather updates. This integration allowed the company to adjust prices, target ads, and reduce inventory costs. Machine learning helped Tacori clean and analyze data, leading to more accurate demand signals and faster decision-making.

Real-time demand sensing helps retailers:

Respond quickly to market changes.

Reduce stockouts and excess inventory.

Improve customer satisfaction by keeping products available.

A table below shows key metrics that improve with real-time demand sensing:

Metric | Description |

|---|---|

Service Level Metrics | Tracks customer satisfaction and wait times |

Adjustment Response Time | Measures speed of implementing changes based on demand signals |

Labor Cost Percentage | Shows workforce cost optimization |

Harnessing Unstructured Data (Social, Weather, Events)

Retailers gain a competitive edge by using unstructured data from social media, weather reports, and local events. Advanced machine learning models, such as BERT and LSTM, process this data to spot trends and predict demand spikes. For instance, social media posts can reveal sudden changes in customer interest or alert teams to local disruptions. Weather data helps stores prepare for storms or heatwaves that affect shopping patterns.

Natural language processing filters out noise and highlights useful information.

Crowd-sourced data reflects real-time community needs and behaviors.

Integrating these sources improves forecast accuracy by up to 30% in some industries.

Retailers who use unstructured data see better labor cost control and higher customer satisfaction.

AI and Machine Learning for Demand Prediction

AI and machine learning transform how retailers predict demand. These technologies analyze large datasets, learn from new information, and adapt to changing market conditions. Companies like Caterpillar use AI-enabled modeling tools to combine internal and external data, which increases forecast accuracy and speeds up planning. Scenario modeling and advanced analytics give deeper insights and help teams make better decisions.

AI models handle complex data and reduce human bias.

Predictive analytics adjust to seasonal trends and market shifts.

Generative AI and neural networks simulate scenarios for more precise forecasts.

Retailers who invest in AI-driven Order Forecast systems see higher operational efficiency, reduced waste, and improved profitability.

Cloud-Based and Automated Forecasting Solutions

Cloud-based and automated forecasting solutions have transformed how retailers manage inventory and respond to market changes. These platforms use artificial intelligence and machine learning to analyze large amounts of data quickly. Retailers can now predict demand with much greater accuracy and adapt to shifting consumer preferences in real time.

Many companies use cloud infrastructure, such as Amazon S3 for data storage and Amazon SageMaker for machine learning model training. Automated workflows, managed by tools like Airflow and Amazon ECS, streamline data pipelines and forecasting processes. This automation reduces manual work and speeds up decision-making.

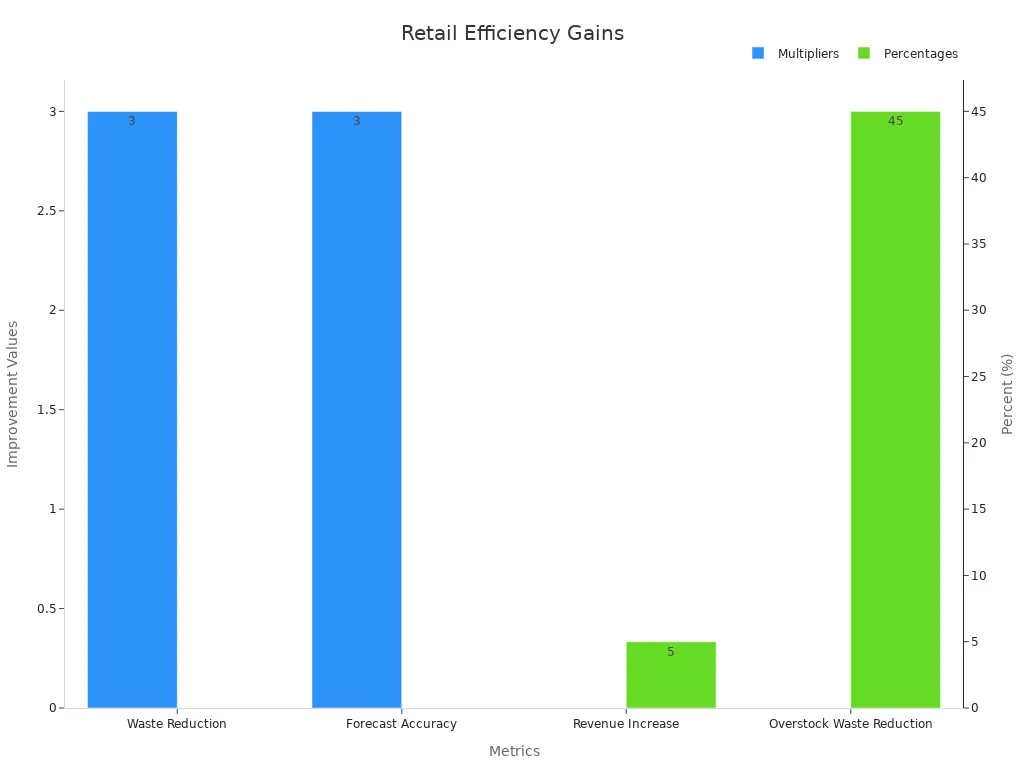

Retailers see clear benefits from these solutions. The table below highlights key improvements:

Metric / Benefit | Description / Result |

|---|---|

Waste Reduction | 3x reduction in waste of coffee beans, pastry, and culinary products |

Revenue Increase | 5% increase in total revenue |

Forecast Accuracy | 3x improvement in demand forecast accuracy |

Overstock Waste Reduction | Up to 45% reduction in overstock waste and associated costs |

Pricing Optimization | Dynamic pricing management based on fluctuating customer demand |

Profitability | Balanced overstock and stockouts to scale profits without operational loss |

Cloud Infrastructure | Use of Amazon S3 for data storage, Amazon SageMaker for ML model training and batch transform |

Workflow Automation | Orchestration via Airflow and Amazon ECS to automate data pipelines and forecasting workflows |

Model Development Pipeline | Continuous enhancement, testing, and selection of best-performing ML models for production use |

Retailers benefit from these solutions in several ways:

AI algorithms provide highly accurate demand predictions, reducing stockouts and overstocks.

Automated forecasting cuts manual effort and speeds up responses to market changes.

Accurate forecasts ensure products stay available, which improves customer experience.

Cloud-based systems help manage perishable goods, reducing waste and keeping shelves stocked.

Early detection of demand changes helps avoid costly overstock or missed sales.

Tip: Retailers who use cloud-based forecasting can make smarter, faster decisions and boost both revenue and customer loyalty.

Breaking Down Silos for Order Forecast Success

Cross-Functional Collaboration Between Operations, Marketing, and Supply Chain

Retail organizations often struggle when departments work in isolation. Silos form when teams focus on their own goals instead of the company’s bigger picture. This leads to poor communication, wasted resources, and slow decision-making. Teams may duplicate work or miss important information, which hurts forecasting accuracy.

Decision-makers lose time searching for data, which lowers productivity.

Disconnected processes lead to missed opportunities and wasted effort.

Companies that encourage cross-functional collaboration see real benefits. Apple grew its revenue from $7 billion in 1997 to $394 billion in 2022 by using cross-functional product teams. Amazon’s integrated approach helped boost revenue by 11.9% in 2023. Henkel’s teams respond faster to market changes and coordinate better between sales and customer operations.

Key performance indicators for collaboration include:

Faster order fulfillment times

Higher inventory turnover

Improved customer satisfaction scores

Open communication and shared goals help teams align their efforts, leading to more reliable forecasts and better business results.

Building Agile, Data-Driven Forecasting Teams

Agile, data-driven teams help retailers adapt quickly to market changes. These teams use data and analytics to make informed decisions. They break down barriers between departments and share information freely.

The table below shows how agile teams improve business outcomes:

Focus Area | Challenge | Data-Driven Approach | Outcome |

|---|---|---|---|

Inventory and Supply Chain Management | Managing diverse products, avoiding overstock | Predict demand using sales history and market trends | 20% lower inventory costs, better supply |

Sales and Operations | Plateau in sales, fewer repeat customers | Predict repeat purchases using customer data | 18% more repeat sales, higher value |

Customer Segmentation and Marketing | Broad segmentation misses behavior patterns | Segment customers with probabilistic models | More targeted marketing, higher revenue |

Risk Management and Fraud Detection | High risk of fraud in digital retail | Predict fraud using transaction and user behavior data | 35% less fraud, safer market expansion |

Agile teams use unified data platforms and automation tools. They access real-time data and share insights across the company. This approach supports faster decisions and better forecasting.

Companies that build agile, data-driven teams can respond quickly to change, reduce risk, and improve overall performance.

Human-AI Collaboration in Order Forecasting

Empowering Planners with AI-Driven Insights

AI-driven insights give planners the tools to make faster and more accurate decisions. These systems analyze large datasets, detect patterns, and adapt to market shifts. Planners use dashboards that display real-time forecasts, confidence intervals, and seasonality patterns. AI models update predictions by comparing them with actual results, refining parameters to stay accurate as conditions change.

In manufacturing, AI anticipates demand changes and aligns procurement schedules.

In automotive distribution, AI predicts demand for parts using sales history and regional data.

In consumer packaged goods, AI manages seasonal spikes and improves shelf availability.

Planners benefit from AI embedded in business workflows. They receive actionable insights through dashboards and ERP systems. This integration allows them to react quickly to promotions or sudden demand shifts. AI-powered forecasting reduces stockouts and overstocking, improving supply chain agility. Flexible models and automated local insights help planners customize forecasts for specific needs.

AI empowers planners to make proactive decisions, optimize inventory, and reduce surprises in daily operations.

Training and Engaging Frontline Employees

Frontline employees play a key role in accurate forecasting. Effective training programs boost their confidence and productivity. Companies use knowledge assessments, operational error tracking, and productivity metrics to measure training impact. Employee engagement rises with open communication, continuous feedback, and recognition.

Metric / KPI | Description |

|---|---|

Tests before and after training show knowledge gains. | |

Operational Error Rates | Fewer mistakes and safety incidents after training. |

Productivity Metrics | Higher output and faster service delivery. |

Customer Satisfaction Scores | Better customer experience linked to training. |

Employee Engagement Indicators | Higher job satisfaction and confidence. |

Managers observe skill application in real work, analyze performance data, and gather feedback through surveys. Digital learning tools track engagement and completion rates. These steps help companies identify skill gaps and tailor training. Engaged employees contribute valuable insights, leading to better operational outcomes and improved forecast accuracy.

Real-World Order Forecast Transformation Examples

Integrating New Data Sources for Improved Forecasts

Retailers are transforming their forecasting capabilities by integrating diverse data sources. Combining online sales, in-store transactions, and social media trends allows businesses to uncover hidden patterns and relationships. Machine learning plays a pivotal role in analyzing this data, enabling more accurate predictions and better decision-making. For example, telecom and home goods retailers have improved forecast accuracy by 10 to 20 percentage points by incorporating external signals like weather and geopolitical events.

In the chemicals industry, poor forecasting accuracy (40% to 50%) often results in holding two to three times more inventory than peers. By integrating unstructured customer inputs, such as emails and calls, and analyzing them with AI, companies achieve faster and more precise forecasting. This approach enhances inventory management, customer engagement, and sales performance, showcasing the transformative potential of new data sources.

Tip: Retailers should prioritize integrating external data sources to gain a competitive edge in demand forecasting.

Overcoming Legacy System Barriers

Legacy systems often hinder forecasting accuracy due to their rigidity and inability to scale. Retailers face challenges such as maintenance complexity, integration difficulties, and limited real-time capabilities. Modernization efforts, including cloud migration and agile re-engineering, address these issues effectively. For instance, hybrid cloud solutions enable faster responses to market changes, while IoT integration improves supply chain visibility.

A study highlights the measurable benefits of overcoming legacy barriers:

Sector | Challenges Identified | Modernization Approach | Quantitative Improvements |

|---|---|---|---|

Retail | Rigid legacy systems limiting market response | Hybrid cloud, agile re-engineering, data analytics | 50% faster response to market changes, increased sales conversion, better customer experience |

These advancements not only enhance forecasting capabilities but also improve operational agility and customer satisfaction. Gartner emphasizes that modernizing IT infrastructure is essential for resilience and long-term growth.

Cross-Departmental Collaboration in Practice

Cross-departmental collaboration is a cornerstone of successful forecasting transformations. By integrating insights from sales, inventory management, and data science teams, retailers achieve better alignment between forecasted demand and supply planning. For example, supply chain optimization cases demonstrate how collaborative efforts improve demand forecasting accuracy and reduce costs.

Retail case studies reveal that collaboration between data scientists, inventory managers, and sales teams enables the effective use of machine learning. This teamwork results in optimized inventory levels, fewer stockouts, and higher customer satisfaction. Practical steps, such as involving key stakeholders and fostering open communication, ensure that diverse perspectives contribute to more effective predictive analytics.

Callout: Collaboration across departments not only enhances forecasting accuracy but also strengthens overall operational efficiency.

Practical Steps to Address Overlooked Gaps in Order Forecast

Assessing Current Forecasting Processes and Data Flows

Retailers begin by evaluating their current forecasting and data flow processes. They use several types of operational reports to understand how information moves through the business:

Current information reports show real-time data about equipment, labor, and tools.

Planning reports provide details on work schedules, employee availability, and inventory status.

Predictive analysis reports help managers plan for future resource needs.

Historical trend reports analyze past equipment reliability and staff performance.

Business intelligence dashboards combine these data sources into visual formats. Leaders can monitor sales growth, customer segments, and financial metrics at a glance. This assessment helps identify gaps in data quality, integration, and reporting. Retailers use these insights to spot trends, manage supply chains, and improve productivity.

Prioritizing Investments in Data, Technology, and Training

Retailers see strong returns when they invest in advanced technology, data, and employee training. Many CFOs now direct billions toward generative AI and analytics to improve forecasting and business operations. Companies with effective data strategies respond faster to trends and make better decisions. Advanced technology and skilled teams turn raw data into actionable insights, which leads to higher profitability.

Big data analytics also boosts innovation and performance. Retailers who focus on technology and training gain more accurate forecasts and adapt quickly to market changes. These investments help teams visualize data, optimize decisions, and improve business outcomes.

Fostering a Culture of Continuous Improvement and Agility

A culture of continuous improvement and agility drives better forecasting results. Retailers use small, steady changes to refine their processes. The Kaizen philosophy encourages learning and adaptability. Teams analyze customer data and make targeted adjustments, which leads to better experiences and fewer errors.

Iterative refinement helps companies fine-tune their models.

Cross-functional reviews involve operations, marketing, finance, and frontline staff.

Real-time data and feedback loops allow quick adjustments.

Regular training workshops help staff interpret sales patterns and adjust inventory.

Retailers document learnings and align forecasts with business goals. Cloud-based tools and mobile access let teams monitor and update forecasts in real time. These practices improve accuracy, efficiency, and strategic alignment.

Retailers who embrace true digital transformation see measurable gains in Order Forecast accuracy. Recent research on listed companies shows that digital initiatives improve forecast precision, especially in competitive markets. Teams that focus on data integration, technology upgrades, and collaboration unlock new business value. Human-AI synergy further enhances forecasting capabilities. Now is the time for retailers to reassess strategies and close critical gaps for long-term success.

FAQ

What is digital transformation in retail?

Digital transformation in retail means using technology to improve business operations. Retailers use new tools and systems to manage inventory, sales, and customer service. This process helps companies stay competitive and meet changing customer needs.

Why do retailers struggle with forecasting accuracy?

Retailers often face challenges with forecasting because they rely on outdated systems or incomplete data. Siloed teams and lack of real-time information also make it hard to predict demand. Upgrading technology and sharing data can improve results.

How does real-time data help retailers?

Real-time data gives retailers instant updates on sales, inventory, and customer trends. This information helps them make quick decisions, avoid stockouts, and respond to market changes. Using real-time data leads to better business outcomes.

What role do frontline employees play in digital transformation?

Frontline employees collect important data and interact with customers daily. Their feedback and engagement help companies spot trends and fix problems quickly. Training and involving these employees ensures new systems work well.

How can retailers break down silos between departments?

Retailers can encourage teams to share information and work toward common goals. Regular meetings, shared dashboards, and open communication help departments align their efforts. Collaboration leads to faster decisions and better performance.

See Also

Effective Weekly Retail Demand Prediction Techniques And Methods

Practical Insights On Consumption Trends From Data-Driven Retail

The Reasons Static Delivery Schedules Collapse In Same-Day Retail

How Artificial Intelligence Is Revolutionizing Retail Shopping Today

Creating A Data-Based Stage-Gate Process For Retail Launches