Layered Architecture of an AI-Enabled Cross-Border Supply Chain

You face unique challenges in managing cross-border supply chains, from unpredictable demand to complex logistics. A layered architecture simplifies these complexities by organizing operations into distinct layers. This design helps you address issues like interoperability and miscommunication. It also promotes standardization, improving collaboration among global stakeholders.

AI-enabled systems further enhance this structure. They boost forecasting precision by 5% and accelerate supplier lead times by up to 60%. With this approach, you can scale operations efficiently while adapting to new technologies. The result is a supply chain that’s more agile, efficient, and ready to meet global demands.

Key Takeaways

Layered design makes supply chains easier by splitting tasks into parts. This helps with managing and changing them quickly.

AI tools make supply chains faster by guessing demand, cutting wait times, and tracking shipments live.

Strong partner links and shared tools help teams work together better. This improves data sharing and how things run.

Using tools like blockchain and IoT keeps data safe. It also makes cross-border deals clearer and more trustworthy.

Focus on affordable, flexible tools that help for a long time. This keeps your supply chain strong and competitive.

Understanding the Layered Architecture

Definition and purpose of layered architecture in supply chains

Layered architecture organizes your supply chain into distinct functional layers. Each layer focuses on specific tasks, such as data collection, partner collaboration, or customer experience. This structure simplifies complex operations by breaking them into manageable components. It also ensures that changes in one layer do not disrupt the others, making your system more adaptable.

For example, in a farm-to-fork supply chain, layered architecture enables tailored solutions for different stakeholders. Producers, logistics providers, and consumers benefit from automated transactions and quality audits. Similarly, in industries like wood-based panels, this approach enhances data security and reliability while protecting connected devices.

Use Case | Benefits | Stakeholders |

|---|---|---|

Farm-to-Fork | 1. Tailored solutions; 2. Automated transactions; 3. Quality audits | Producers, farms, manufacturers, logistics, consumers |

Wood-based Panels | 1. Security at integration layers; 2. Data integrity; 3. Cybersecurity | Raw material suppliers, logistics, industrial clients |

Securing Autonomous Driving | 1. Secure environments; 2. Sensor certification; 3. Data collection | OEMs, software developers, edge providers, end users |

Key principles of designing a layered architecture

Designing an effective layered architecture requires you to follow key principles. Structured dependencies ensure that upper layers can evolve independently from lower ones. This makes your system scalable and easier to modify. Modular design further enhances flexibility by allowing you to update or replace individual components without affecting the entire system.

In some cases, loose layering can improve performance. This approach allows layers to access multiple lower layers, increasing adaptability. For instance, a shared services layer might interact directly with both the ingestion and database layers to optimize data flow. By adhering to these principles, you can create a supply chain system that balances efficiency and adaptability.

Relevance of layered architecture in cross-border operations

Cross-border supply chains face unique challenges, such as high data volumes, regulatory compliance, and multi-party collaboration. Layered architecture addresses these issues by providing a scalable and secure framework.

Consider the "3 + 1" architecture used in global operations. It integrates production, port, and sales chains with a cross-chain management platform. This setup handles 1,400 concurrent users with a query latency below 600ms, outperforming traditional systems. Additionally, advanced cryptographic algorithms like SM2 enhance data security while maintaining high throughput.

This approach also resolves data silos, enabling seamless collaboration among stakeholders. By adopting layered architecture, you can build a supply chain that supports growth, ensures compliance, and fosters trust in international partnerships.

Core Layers of an AI-Enabled Cross-Border Supply Chain

Ingestion Layer: Data collection, preprocessing, and integration

The ingestion layer serves as the foundation of your AI-enabled supply chain. It collects data from multiple sources, preprocesses it to ensure quality, and integrates it into a unified system. This layer enables you to harness the power of real-time data, which is critical for making informed decisions in cross-border operations.

You can use advanced tools like Apache Kafka and Apache Spark to build robust data pipelines. These tools allow you to process data from IoT devices, sensors, and partner systems efficiently. For example:

Company X improved operational insights by implementing a real-time data ingestion pipeline.

Retail Company Y unified customer data from various sources, enhancing customer experience and driving revenue growth.

By leveraging the ingestion layer, you can transform raw data into actionable insights, ensuring your supply chain remains agile and responsive to global demands.

Partner Connectivity Layer: Enabling seamless collaboration with global partners

The partner connectivity layer focuses on creating a seamless network for collaboration among your global stakeholders. It ensures that partners can share data securely, communicate effectively, and work together to optimize supply chain processes.

This layer enhances operational efficiency by enabling real-time connectivity. It also improves cybersecurity standards, with nearly half of partners actively collaborating on this aspect. Additionally, it increases access to shared data repositories, addressing the needs of stakeholders seeking better data integration.

Tip: Implementing robust APIs and secure communication protocols can strengthen your partner connectivity layer, fostering trust and transparency in cross-border operations.

By prioritizing connectivity, you can build a supply chain ecosystem that thrives on collaboration and mutual growth.

Shared Services Layer: Centralized tools for operational efficiency

The shared services layer provides centralized tools and resources to streamline your supply chain operations. It acts as a hub for managing processes, technologies, and stakeholder interactions, ensuring consistency and efficiency across all layers.

Contribution to Operational Efficiency | |

|---|---|

Stakeholder Interfaces | Critical for performance in cross-border logistics operations |

Integration of Technologies | Enhances process efficiency through better data management and process mining |

Modular Technology Management | Reduces obsolescence and maintenance issues compared to monolithic solutions |

Interactional Dimension | Guides operationalizing supply chain integration by identifying relevant technologies |

Spatial Dimension | Identifies opportunities for process improvement using IoT and RFID technologies |

This layer reduces redundancy and simplifies complex workflows. For example, modular technology management minimizes maintenance issues, while IoT and RFID technologies identify areas for improvement. By centralizing shared services, you can achieve greater operational efficiency and maintain a competitive edge in global markets.

Customer Experience Layer: Enhancing visibility and user satisfaction.

The customer experience layer plays a pivotal role in ensuring that your supply chain meets the expectations of end-users. This layer focuses on enhancing visibility, improving communication, and delivering satisfaction through seamless interactions. By prioritizing this layer, you can build trust and loyalty among your customers.

Visibility is a cornerstone of this layer. When customers can track their shipments in real-time, they feel more confident in your services. Tools like AI-powered dashboards and predictive analytics provide accurate updates on delivery timelines. For instance, a retailer using these tools can notify customers of potential delays before they occur, turning a negative experience into a positive one.

You can also use this layer to personalize customer interactions. AI algorithms analyze purchasing patterns and preferences, enabling you to offer tailored recommendations. For example, if a customer frequently orders products from a specific region, your system can suggest similar items or faster shipping options for that area. Personalization not only boosts satisfaction but also drives repeat business.

Communication is another critical aspect. Chatbots powered by natural language processing (NLP) can handle customer inquiries efficiently. These bots provide instant responses to common questions, such as shipment status or return policies. By automating routine interactions, you free up resources to focus on more complex customer needs.

Tip: Integrate real-time tracking tools and AI-driven personalization features to elevate the customer experience layer. These enhancements can transform your supply chain into a customer-centric ecosystem.

When you optimize the customer experience layer, you create a supply chain that not only delivers products but also builds lasting relationships with your customers.

Database Layer: Secure, scalable, and efficient data storage.

The database layer underpins your entire supply chain by providing a secure and scalable foundation for data storage. This layer ensures that your data remains accessible, reliable, and protected from unauthorized access. By investing in robust database solutions, you can support the growing demands of cross-border operations.

Scalability is a key feature of this layer. As your supply chain expands, the database must handle increasing volumes of data without compromising performance. Cloud-based storage solutions offer the flexibility to scale up or down based on your needs. For example, during peak seasons, you can allocate additional resources to manage higher data loads, ensuring uninterrupted operations.

Security is equally important. Cross-border supply chains involve sensitive information, such as trade documents and financial records. Integrating blockchain technology with cloud-based storage enhances security and trustworthiness. Blockchain creates an immutable ledger, preventing unauthorized modifications to your data. Decentralized data management further strengthens security by reducing the risk of single points of failure.

Efficient data sharing is another advantage of a well-designed database layer. Robust access control mechanisms safeguard your data while allowing authorized stakeholders to access the information they need. For instance:

Blockchain ensures data integrity and facilitates seamless exchange between global partners.

Advanced cryptographic algorithms protect sensitive data during transmission.

Note: Implementing decentralized data management and secure sharing protocols can address interoperability issues, which are common in cross-border supply chains.

By optimizing the database layer, you create a solid foundation for your layered architecture. This ensures that your supply chain remains resilient, efficient, and ready to adapt to future challenges.

AI Technologies Optimizing the Layered Architecture

Machine Learning: Predictive analytics and demand forecasting

Machine learning (ML) plays a transformative role in optimizing supply chains by enabling predictive analytics and demand forecasting. It helps you anticipate future trends, reduce inefficiencies, and make data-driven decisions. By analyzing historical data, ML algorithms identify patterns that allow you to predict demand, optimize inventory, and improve operational planning.

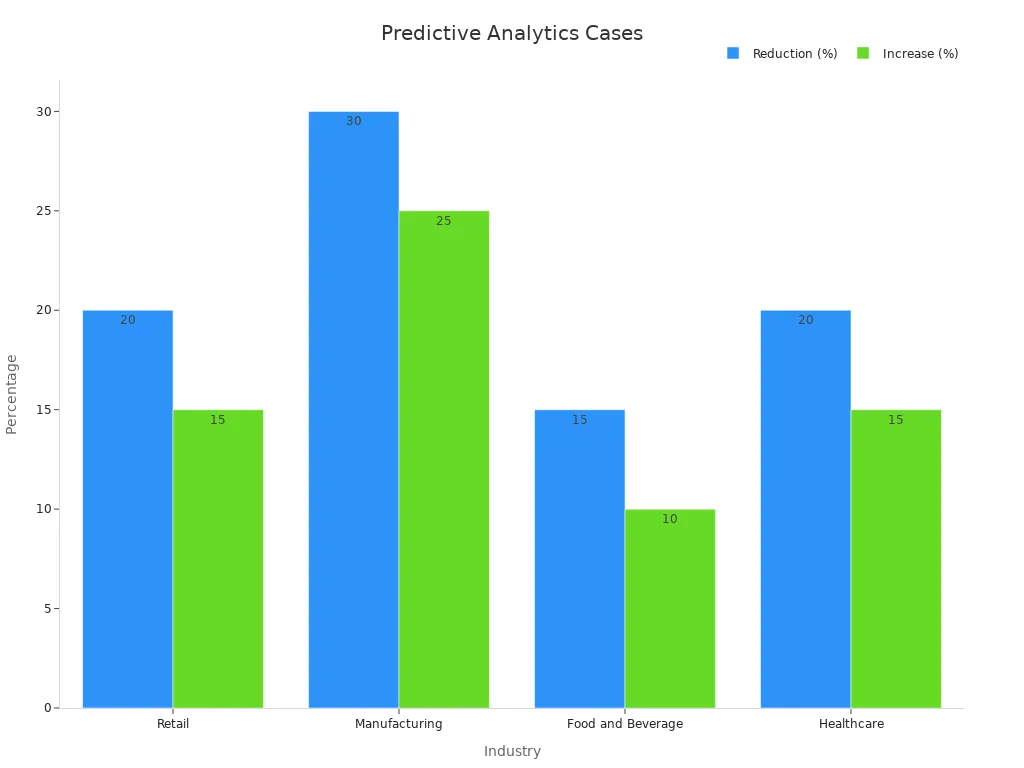

For example, in the retail industry, ML can analyze customer purchase patterns to forecast demand, reducing stockouts and increasing sales. In manufacturing, it predicts equipment failures, helping you schedule maintenance and minimize downtime. The food and beverage sector benefits from ML by forecasting demand based on historical sales data, reducing inventory costs and improving delivery timelines. The table below highlights these applications and their results:

Industry | Application of Predictive Analytics | Results Achieved |

|---|---|---|

Retail | Analyzed customer purchase patterns to forecast demand. | |

Manufacturing | Predicted equipment failures to optimize maintenance schedules. | 30% reduction in downtime, 25% increase in production efficiency. |

Food and Beverage | Analyzed historical sales data to forecast future demand. | 15% reduction in inventory holding costs, 10% increase in on-time deliveries. |

Healthcare | Predicted demand for medical supplies during the COVID-19 pandemic. | 20% reduction in stockouts, 15% increase in on-time deliveries. |

By leveraging ML for predictive analytics, you can enhance your supply chain's resilience and efficiency, ensuring you stay ahead of market demands.

IoT: Real-time tracking and monitoring of shipments

The Internet of Things (IoT) revolutionizes shipment tracking and monitoring by providing real-time data across your supply chain. IoT devices, such as GPS trackers and sensors, enable you to monitor shipments continuously, ensuring timely deliveries and maintaining product quality.

Here’s how IoT enhances shipment monitoring:

Continuous Location Tracking: GPS trackers provide live updates on shipment locations, allowing you to adjust logistics operations quickly.

Condition Monitoring: Sensors track environmental factors like temperature and humidity, which is crucial for perishable goods.

Real-Time Alerts: Automated notifications warn you of temperature deviations, helping you prevent spoilage.

Geolocation Monitoring: GPS data detects unauthorized route changes, enhancing security and reducing theft risks.

For instance, if you manage a supply chain for pharmaceuticals, IoT sensors can ensure that temperature-sensitive medicines remain within safe ranges during transit. This level of monitoring not only protects your products but also builds trust with your customers.

By integrating IoT into your supply chain, you gain unparalleled visibility and control, enabling you to respond proactively to challenges and maintain operational excellence.

Natural Language Processing: Automating communication and documentation

Natural Language Processing (NLP) simplifies communication and documentation in supply chains by automating tasks that traditionally required manual effort. This technology helps you save time, reduce costs, and improve accuracy in managing supply chain operations.

NLP offers several advantages:

It automates customer inquiries and data entry, reducing operational costs.

It processes data faster, enabling you to respond quickly to changes in supply chain dynamics.

It enhances predictive analytics, helping you forecast trends and prepare for disruptions.

Cost Reduction: Nearly half of global manufacturers use NLP to predict maintenance needs, cutting operational costs significantly.

Improved Forecasting: NLP algorithms analyze data to predict future trends, making your supply chain more resilient.

Enhanced Reliability: By automating communication, NLP creates a more dependable logistics network, boosting stakeholder trust.

For example, chatbots powered by NLP can handle routine customer queries, such as shipment status or return policies, freeing up your team to focus on complex issues. Additionally, NLP systems can analyze trade documents and generate reports, streamlining your documentation process.

Tip: Incorporate NLP-driven chatbots and automated documentation tools to enhance efficiency and reduce manual errors in your supply chain.

By adopting NLP, you can transform your supply chain into a smarter, more agile system that adapts seamlessly to the demands of global operations.

Robotics and Automation: Streamlining warehouse and logistics operations.

Robotics and automation have revolutionized how you manage warehouses and logistics in cross-border supply chains. These technologies eliminate manual inefficiencies, reduce errors, and accelerate processes, ensuring your operations remain competitive in a global market.

AI-powered transportation management systems and warehouse robotics form the backbone of logistics automation. Robots handle tasks like sorting, packing, and palletizing goods with precision and speed. This reduces human error and ensures consistent quality. For example, automated guided vehicles (AGVs) transport goods within warehouses, optimizing space utilization and minimizing delays.

Robotic Process Automation (RPA) further enhances efficiency by automating repetitive tasks. You can use RPA for invoicing, shipment tracking updates, and customs documentation. These applications save time and reduce manual effort. FedEx, for instance, employs RPA-powered bots to handle customer service inquiries. This approach has significantly reduced wait times and improved operational efficiency.

Did you know? The World Economic Forum estimates that AI-enabled trade facilitation, including automated customs processing, could boost global GDP by $1 trillion annually. By adopting these technologies, you not only streamline operations but also contribute to global economic growth.

Automation also simplifies international trade. AI algorithms process customs paperwork automatically, reducing delays at borders. This ensures faster delivery times and enhances customer satisfaction. When you integrate robotics and automation into your supply chain, you create a system that is faster, more accurate, and ready to meet the demands of cross-border operations.

Blockchain: Ensuring data security and trust in cross-border transactions.

Blockchain technology addresses one of the most critical challenges in cross-border supply chains: ensuring data security and trust. By creating a decentralized and immutable ledger, blockchain provides a transparent and tamper-proof system for managing transactions.

Each transaction on a blockchain is cryptographically sealed, making it nearly impossible to alter or tamper with the data. This level of security protects sensitive information, such as trade documents and financial records, from unauthorized access. For example, when you use blockchain to manage your supply chain, you reduce the risk of counterfeit goods entering the system.

Transparency is another key advantage. Blockchain allows all participants in the supply chain to access and verify transaction histories. This fosters trust among stakeholders, as everyone can see the same version of the truth. For instance, if you are a retailer, you can trace the origin of a product back to its source, ensuring compliance with quality standards.

Tip: Use blockchain to enhance traceability in your supply chain. This not only improves operational efficiency but also builds trust with your customers.

Blockchain also reduces fraud by maintaining immutable records. This is particularly important in industries like pharmaceuticals, where counterfeit drugs pose significant risks. By integrating blockchain, you ensure that only authentic products reach your customers.

When you adopt blockchain technology, you create a secure and transparent supply chain. This not only protects your operations but also strengthens relationships with partners and customers, ensuring long-term success in cross-border trade.

Challenges and Solutions in Implementation

Scalability: Managing increasing data and operational demands

Scaling your supply chain to handle growing data volumes presents unique challenges. Rapid success in eCommerce often leads to logistical chaos if systems are not prepared. Increased data during peak periods can overload your infrastructure, causing tracking inaccuracies and shipment delays. Balancing speed and accuracy becomes critical as data volumes rise, directly impacting inventory levels and profitability.

To address these challenges, you need robust systems and partnerships. Real-time tracking tools ensure operational efficiency and prevent bottlenecks. Predictive analytics can help you forecast inventory needs, reducing the risk of stock shortages or over-ordering. Fragmented supply chains exacerbate inefficiencies, so integrating data across layers is essential for smooth scaling.

Tip: Implement cloud-based solutions to handle peak data loads and maintain system performance during high-demand periods.

Partner Integration: Overcoming system compatibility issues

Integrating systems with global partners often proves difficult due to compatibility issues. Data silos, where information is stored in separate repositories, make collaboration time-consuming. Many organizations rely on dashboards for past performance rather than predictive analytics, limiting their ability to plan for the future. Inconsistent data further complicates decision-making, eroding trust among stakeholders.

You can overcome these barriers by adopting standardized APIs and secure communication protocols. These tools enable seamless data sharing and foster collaboration. Clear governance structures also ensure accountability in managing AI models, improving trust and decision-making.

Note: Centralized data repositories and real-time analytics can bridge gaps between partners, enhancing integration and operational efficiency.

Compliance: Navigating international trade regulations and standards

International trade regulations create significant hurdles for your supply chain. Supply chain disruptions affect 74% of businesses, while geopolitical export control laws impact 52%. Retaliatory tariffs and ESG (Environmental, Social, and Governance) issues further complicate compliance. These factors increase costs and delay operations, making it harder to maintain efficiency.

To navigate these challenges, you must stay updated on regulatory changes and invest in AI-driven compliance tools. These systems analyze trade laws and automate documentation, reducing errors and ensuring adherence to standards. Blockchain technology can also enhance transparency, helping you meet ESG requirements and build trust with stakeholders.

Tip: Use AI-powered tools to monitor regulatory changes and automate compliance processes, ensuring your supply chain remains agile and compliant.

Cost Management: Balancing investment with long-term ROI.

Effective cost management in cross-border supply chains requires balancing initial investments with long-term returns. You need to focus on strategies that optimize resources while delivering measurable financial benefits. This approach ensures your supply chain remains competitive and sustainable.

Investing in technologies like AI and IoT may seem costly upfront, but the long-term ROI often outweighs the initial expenses. For example:

A study from the NYU Stern Center found that 58% of research papers showed a positive relationship between ESG investments and financial performance.

UPS saves 100 million miles and 10 million gallons of fuel annually through route optimization, showcasing significant cost savings.

Companies with highly engaged teams experience a 21% increase in profitability, along with reduced absenteeism and turnover rates.

The average annual supply management ROI across industries is 635.9%. This means for every dollar you invest, $6.36 is returned. This metric highlights the value of strategic investments, especially when compared to the average return on the S&P 500. By leveraging these insights, you can communicate the financial benefits of supply chain optimization effectively.

To maximize ROI, focus on scalable solutions that grow with your operations. Route optimization tools, predictive analytics, and centralized data systems reduce inefficiencies and improve decision-making. These technologies not only lower costs but also enhance productivity, ensuring your supply chain delivers consistent value over time.

Tip: Prioritize investments in technologies that offer measurable long-term benefits. This strategy helps you achieve cost efficiency while maintaining operational excellence.

Cybersecurity: Protecting sensitive data in cross-border operations.

Cybersecurity is critical for safeguarding sensitive data in cross-border supply chains. You must address vulnerabilities that arise from multi-party collaborations and third-party software integrations. Without robust security measures, your operations risk exposure to costly breaches.

Supply chain cyber attacks often exploit trust in suppliers’ security systems. For example:

Statistic | Description |

|---|---|

Exploited trust in suppliers’ security, indicating a vulnerability in cross-border operations. | |

36% of cybersecurity decision makers | Feel more responsible for preventing supply chain attacks than their suppliers, highlighting accountability. |

Supply chain attacks expected to multiply by 4 in 2021 | Indicates a significant increase in risk for sensitive data in supply chains. |

16% of all breaches caused by weaknesses in third-party software | Emphasizes the need for robust security measures in cross-border supply chains. |

42% rise in supply chain attacks in Q1 2021 | Coupled with a 10% increase in the average cost of a data breach, stressing the financial impact. |

60% of supply chain workers not monitoring third-party vendors for risks | Suggests a lack of vigilance that could lead to data breaches in cross-border operations. |

These statistics highlight the importance of proactive cybersecurity measures. Blockchain technology can help mitigate risks by creating an immutable ledger for transactions. This ensures data integrity and prevents unauthorized modifications. Additionally, AI-powered monitoring tools detect anomalies in real-time, enabling you to respond swiftly to potential threats.

Note: Regularly audit third-party vendors and implement advanced encryption protocols to strengthen your supply chain’s security framework.

By prioritizing cybersecurity, you protect your operations from disruptions and build trust with global partners. This not only safeguards sensitive data but also ensures the long-term success of your cross-border supply chain.

Benefits and Future Trends in AI-Enabled Supply Chains

Enhanced efficiency and cost reduction through automation

Automation has revolutionized supply chain operations, delivering measurable improvements in efficiency and cost savings. By integrating AI-driven tools, you can streamline processes, reduce manual errors, and optimize resource allocation. For instance, British Petroleum leveraged automation to save $100 million through automated sourcing, cutting cycle times by 50%. This demonstrates how automation directly correlates with cost efficiency.

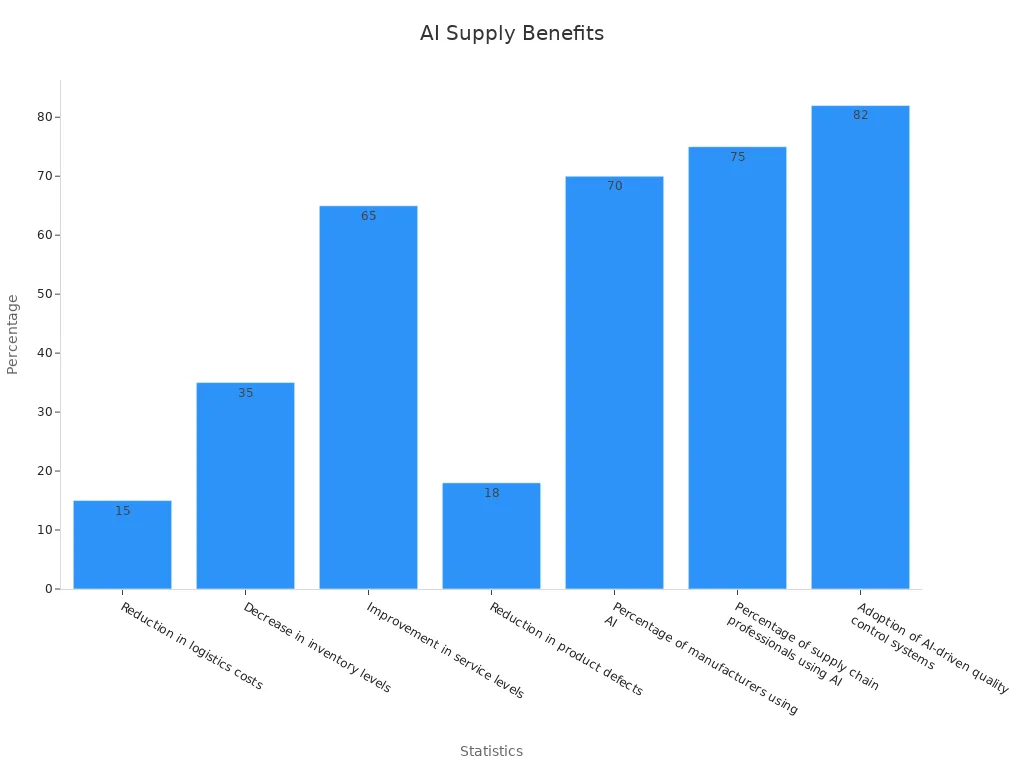

AI also enhances logistics and inventory management. Companies that adopt AI report significant benefits, including a 15% reduction in logistics costs and a 35% decrease in inventory levels. These improvements free up capital and reduce storage expenses. Additionally, service levels improve by 65%, boosting customer satisfaction.

Statistic Description | Value |

|---|---|

Reduction in logistics costs | 15% |

Decrease in inventory levels | 35% |

Improvement in service levels | 65% |

Reduction in product defects | 18% |

Percentage of manufacturers using AI | 70% |

Percentage of supply chain professionals using AI | 75% |

Adoption of AI-driven quality control systems | 82% |

By automating repetitive tasks and optimizing workflows, you can achieve long-term cost savings while maintaining operational excellence.

Improved decision-making with data-driven insights

Data-driven insights empower you to make informed decisions, enhancing transparency and agility in your supply chain. Real-time data analysis identifies bottlenecks, predicts demand, and improves logistics. This approach reduces costs and increases profits, ensuring your operations remain competitive.

Leading companies like Procter & Gamble and Walmart demonstrate the power of data-driven strategies. P&G uses data to monitor supplier performance and adapt to consumer preferences, while Walmart leverages analytics to forecast demand and maintain optimal inventory levels. Amazon employs algorithms to personalize customer experiences, further enhancing satisfaction.

Procter & Gamble (P&G): Analyzes supplier performance and consumer trends to improve resilience.

Amazon: Optimizes inventory and personalizes recommendations using advanced algorithms.

Walmart: Forecasts demand accurately, reducing costs and improving inventory management.

Unilever: Enhances sustainability and resource efficiency through data analytics.

By adopting data-driven solutions, you can improve collaboration, foster customer loyalty, and build a more resilient supply chain.

AI advancements shaping the future of global supply chains

AI continues to transform global supply chains by introducing innovative solutions that address complex challenges. Predictive models enhance demand forecasting by analyzing diverse data sources, enabling you to anticipate market trends with greater accuracy. In inventory management, AI automates stock monitoring and replenishment, optimizing costs and cash flow.

Logistics optimization is another area where AI excels. Advanced route planning reduces transportation costs and minimizes environmental impact. Additionally, AI integrates with blockchain technology to improve transparency, ensuring product traceability and regulatory compliance.

AI-driven demand forecasting improves accuracy by analyzing diverse data sources.

Automated inventory management reduces costs and enhances cash flow.

Logistics optimization through AI minimizes transportation expenses and environmental impact.

Blockchain integration ensures transparency and compliance in global operations.

By embracing these advancements, you can future-proof your supply chain, ensuring it remains agile, efficient, and ready to meet evolving global demands.

The role of generative AI in supply chain innovation.

Generative AI is transforming supply chain innovation by introducing advanced automation and customization capabilities. You can use this technology to optimize logistics, enhance efficiency, and meet rising consumer expectations. Its ability to analyze vast amounts of data and generate actionable insights makes it a game-changer in international logistics.

Generative AI addresses key challenges in supply chains. For example, the growing demand for automation has led to the adoption of AI-powered tools that streamline processes. A major US logistics company implemented a proprietary AI platform to optimize warehouse picking routes. This resulted in a 30% increase in workforce productivity and significant cost savings through better space and materials handling.

E-commerce growth has also fueled the need for innovative logistics solutions. Generative AI helps you prioritize deliveries based on factors like urgency and location. This ensures faster and more reliable last-mile logistics, which is crucial for meeting consumer expectations. Additionally, integrating IoT devices with AI enables real-time tracking and predictive analytics, further enhancing supply chain performance.

Factor | Description |

|---|---|

Demand for Automation | Increasing need for automated processes in logistics to enhance efficiency. |

Rising E-commerce Activity | Growth in online shopping necessitating improved logistics solutions for timely deliveries. |

Cost-efficient Solutions | Need for sustainable logistics that reduce costs while maintaining service quality. |

IoT Integration | Use of IoT devices with AI for real-time tracking and predictive analytics in supply chains. |

Last-mile Logistics Enhancement | Adoption of generative AI to meet consumer expectations for fast and reliable deliveries. |

Generative AI also allows you to customize logistics operations. For instance, it can optimize routes for fuel efficiency or adjust schedules to reduce delays. These capabilities not only improve operational performance but also contribute to sustainability. By adopting generative AI, you can build a supply chain that is efficient, adaptable, and ready to tackle future challenges.

Integration of AI with blockchain for secure and transparent operations.

The integration of AI and blockchain creates a secure and transparent foundation for supply chain operations. Blockchain provides an immutable ledger for recording transactions, while AI enhances decision-making through advanced analytics. Together, these technologies address challenges like fraud, inefficiencies, and compliance with regulatory standards.

Blockchain ensures data integrity by maintaining a transparent record of transactions. This feature is particularly useful for reducing fraud and counterfeiting. For example, industries like pharmaceuticals use blockchain to verify the authenticity of products, ensuring only genuine goods reach consumers. AI complements this by analyzing data in real time, enabling you to detect anomalies and respond quickly to potential issues.

Integrating these technologies also improves traceability. Blockchain’s decentralized nature allows all stakeholders to access the same version of the truth, fostering trust and collaboration. AI agents use this data to optimize operations, such as predicting demand or identifying bottlenecks. This combination enhances efficiency and reduces operational costs.

Blockchain ensures immutable, decentralized ledgers for real-time tracking and verification of goods.

AI facilitates advanced analytics and real-time decision-making.

Together, they address challenges such as fraud and inefficiencies in logistics.

Case studies show significant improvements in reducing human errors and enhancing compliance with regulatory standards.

For example, combining blockchain with AI agents creates a transparent supply chain ecosystem. Real-time data from blockchain enhances decision-making, while AI optimizes logistics and inventory management. This integration not only improves operational efficiency but also strengthens customer satisfaction by ensuring timely and accurate deliveries.

By adopting AI and blockchain, you can build a resilient and transparent supply chain. These technologies provide a competitive edge, ensuring your operations remain secure, efficient, and aligned with global standards.

Layered architecture forms the backbone of AI-enabled supply chains, offering a structured approach to manage complexity and enhance scalability. Each layer, from data ingestion to customer experience, benefits from AI technologies that optimize processes and improve decision-making. For example, machine learning enhances demand forecasting, while IoT ensures real-time shipment tracking. These innovations collectively drive efficiency and adaptability.

Statistic | Value |

|---|---|

Reduction in stockouts | |

Decrease in excess inventory | 35% |

Improvement in forecast accuracy | 15% |

Annual savings in carrying costs | $120 million |

Profitability improvement factor | 4.25 times |

Inventory cost reductions | 15-30% |

Transportation cost savings | 5-20% |

Labor productivity improvements | 20-40% |

Service level enhancements | 10-25% |

AI's future impact on cross-border supply chains is immense. It will revolutionize logistics with real-time tracking, optimized routes, and enhanced demand forecasting. Governments are investing in digital infrastructure, while companies adopt AI-powered control towers to mitigate risks. Small enterprises now leverage low-code AI platforms to predict disruptions effectively. These advancements promise a more transparent, efficient, and resilient global supply chain ecosystem.

FAQ

What is the main advantage of using a layered architecture in supply chains?

Layered architecture simplifies complex operations by dividing them into manageable layers. This structure allows you to make changes in one layer without disrupting others. It improves scalability, adaptability, and collaboration, making your supply chain more efficient and resilient.

How does AI improve cross-border supply chain operations?

AI enhances decision-making with predictive analytics, real-time tracking, and automation. It helps you forecast demand, optimize routes, and reduce manual errors. These improvements lead to faster deliveries, lower costs, and better customer satisfaction.

Can small businesses benefit from AI-enabled supply chains?

Yes, small businesses can use low-code AI platforms to predict disruptions, optimize inventory, and improve logistics. These tools are cost-effective and scalable, helping you compete with larger companies in global markets.

How does blockchain ensure security in cross-border supply chains?

Blockchain creates a decentralized, tamper-proof ledger for transactions. It ensures data integrity and transparency, reducing fraud and building trust among stakeholders. You can trace products back to their source, ensuring compliance with quality standards.

What challenges might you face when implementing AI in supply chains?

You may encounter challenges like high initial costs, system integration issues, and data security concerns. To overcome these, invest in scalable technologies, adopt standardized protocols, and prioritize cybersecurity measures.

Tip: Start small with AI tools that address specific pain points, then scale up as you see results.

See Also

The Journey From Automation To Intelligent Supply Chain Solutions

Four Key Algorithms For Large-Scale Daily Replenishment Automation

Merging EOS Systems With ERP And Warehouse Management Solutions

Evaluating ROI: A Comparison Of Vision, RFID, And POS Data

Creating A Centralized Data Mart For Effective S&OP Planning